Iimveliso

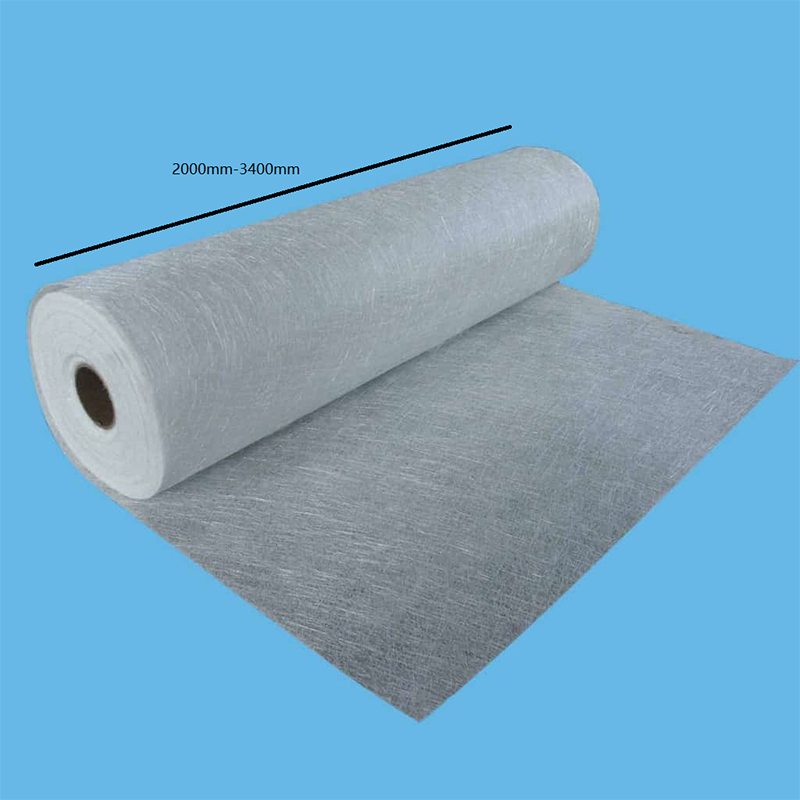

I-Fiberglass Elungiselelweyo I-Big Roll Mat (I-Binder: I-Emulsion kunye nePowder)

Isicelo

I-Fiberglass Customized Big Roll Mat, eyona nto ibalulekileyo kwicandelo leFiber Reinforced Plastics (FRP), isetyenziswa kakhulu kumashishini ahlukeneyo. Ezi mat zisetyenziswa kakhulu kwiinkqubo ezifana nokubeka izinto ngokuzenzekelayo, ukujija i-filament, kunye nokubumba ukwenza uluhlu lweemveliso ezibalaseleyo. Ukusetyenziswa kwe-Fiberglass Customized Big Roll Mat kubandakanya uluhlu olubanzi, oluquka ukwenziwa kwepleyiti enkulu yenqwelo, njengelori efrijiweyo, iveni yemoto kunye nokunye okuninzi.

| Ubunzima | Ubunzima bendawo (%) | Umxholo wobumanzi (%) | Ubungakanani bomxholo (%) | Amandla okuPhuka (N) | Ububanzi (mm) | |

| Indlela | I-ISO3374 | I-ISO3344 | I-ISO1887 | I-ISO3342 | I-ISO 3374 | |

| Umgubo | I-Emulsion | |||||

| EMC225 | 225±10 | ≤0.20 | 3.0-5.3 | 3.0-5.3 | ≥100 | 2000mm-3400mm |

| I-EMC370 | 300±10 | ≤0.20 | 2.1-3.8 | 2.2-3.8 | ≥120 | 2000mm-3400mm |

| I-EMC450 | 450±10 | ≤0.20 | 2.1-3.8 | 2.2-3.8 | ≥120 | 2000mm-3400mm |

| I-EMC600 | 600±10 | ≤0.20 | 2.1-3.8 | 2.2-3.8 | ≥150 | 2000mm-3400mm |

| I-EMC900 | 900±10 | ≤0.20 | 2.1-3.8 | 2.2-3.8 | ≥180 | 2000mm-3400mm |

Izakhono

1. Iimpawu zoomatshini ezisebenzayo kakhulu kunye nokusasazwa okungacwangciswanga.

2. Ukuhambelana okuhle kwe-resin, umphezulu ococekileyo, kunye nokuqina okuhle

3. Ukumelana kakuhle nokufudumeza.

4. Ukwanda kwesantya sokuphuma kwamanzi kunye nesantya

5. Ihambelana neemilo ezinzima kwaye izalisa iimolds ngokulula

Indawo yokugcina izinto

Iimveliso ezenziwe ngefiberglass mazigcinwe zomile, zibanda, kwaye zingabi namanzi ngaphandle kokuba kuchazwe ngenye indlela. Umswakama kwigumbi kufuneka uhlale uphakathi kwama-35% nama-65% kwaye uphakathi kwama-15°C nama-35°C, ngokwahlukeneyo. Ukuba kunokwenzeka, sebenzisa kungekapheli unyaka emva komhla wokwenziwa. Izinto zefiberglass mazisetyenziswe zisuka nje kwibhokisi yazo yokuqala.

Ukupakisha

Iroli nganye ibekwa ngokuzenzekelayo ize ipakishwe kwipalethi eyenziwe ngomthi. Iroli ibekwa ngokuthe tye okanye ngokuthe nkqo kwiipalethi.

Zonke iipalethi zisongiwe kwaye zibotshelelwe ukuze zihlale zizinzile ngexesha lokuthuthwa.